Whenever anyone asks me:

What’s your one piece of advice for new designers?

I always have the same answer. I’ve worked with hundreds of entrepreneurs over the years, and I warn all of them of the same mistakes that I made when I was first starting out in the fashion industry.

Let me take you back to the summer of 2012. I’m living out of a 1993 Chevy Conversion van on a three-month “sustainable fashion tour” of the Pacific Northwest.

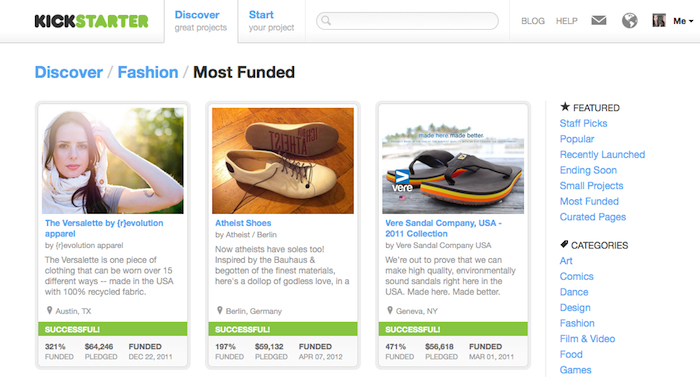

Six months prior, my co-founder and I had launched the highest-funded fashion project in Kickstarter history to fund the production of our first piece, the Versalette by {r}evolution apparel. We were on a mission to shake up the fashion industry, to prove that less is more, and to show everyone that conscious consumerism can change the world.

By working with a sew shop in the U.S., sourcing 100% recycled, U.S.-made fabric, and considering every tiny part of our supply chain, we had attracted the attention of 1,400 first customers, in addition to media outlets such as The New York Times.

But that’s not where we started.

My journey into fashion production began a year and a half earlier when my co-founder and I first came up with the idea to start a “sustainable clothing company.” We had no idea what that really meant, so we blindly began contacting any person we thought had the slightest chance of helping us.

We called organic cotton farmers in Texas, environmental studies professors in Missouri, eco-fashion models in Brooklyn, Merino wool suppliers in New Zealand and the list goes on…

Looking back at the emails I sent to suppliers, I know now that my inquiries surely got a swift click of the delete button. I didn’t know how to talk to industry veterans, I had no idea how to talk “the talk,” and it showed.

Eventually though, after a year and a half of trying, we found fabric and materials that fit our sustainability guidelines, a sew shop who would work with a fledgling startup, and that’s when we successfully funded our Kickstarter campaign.

If we thought sourcing was difficult, we couldn’t have imagined what the production process had in store for us.

First hurdle, the organic cotton drawstrings we needed were on backorder and the sew shop couldn’t move forward until they had all materials in-house. We got bumped off their production calendar and couldn’t get back on until the drawstrings arrived.

By the time we began production, we were running four months late.

The backordered drawstrings, production delays and an additional shipping fiasco were rookie mistakes we had to live with and learn from.

But the next mistake we made was the biggest one of all — and it’s the only thing from this story that you really need to remember:

We weren’t at the sew shop when production started.

Sure, we signed off on samples and patterns, but the worst decision we made was not being with our production team when Versalettes started coming off the line.

We weren’t there to offer additional quality control, answer questions in person, build relationships with our sewers and get them invested in our project.

And it came back to bite us.

Our first shipment of Versalettes arrived and a third of them had crooked pockets, misplaced button holes, lost drawstrings or unfinished seams. We got a second shipment and it had the same problem. The sew shop was sending us batches of 40 units at a time and instead of being thrilled to open them, I was terrified.

At the time, it would have been easy to blame the sewers for being “unskilled,” but that simply wasn’t the truth.

Being completely new to the industry, we didn’t know how crucially important it was to a build relationships with our sew shop and be there at the beginning of production.

We had no one to blame but ourselves.

When you’re first starting out, trying to do design and marketing and media outreach and customer service and blogging and everything else yourself, it can be easy to take production for granted and assume someone else is handling it.

The thing is, no one is ever going to care about your product as much as you do.

After we received our second batch of Versalettes, I flew to North Carolina to visit our sew shop and work out the “kinks.” I spoke to each sewer individually, shared the article about us from The New York Times, and showed them photos of our models wearing the Versalette.

Spending a few days with our team, I finally understood that relationship building in the manufacturing industry is no different than in any other industry.

Shortly after I flew back to the west coast, our third shipment arrived.

Not a mistake in the bunch.

This originally appeared as a guest post on Startup FASHION here.