This is a guest post from Brianna Kilcullen, the founder of Anact and a student of my Kickstarter course, The Crowdfunding Factory.

Today she’s sharing three things she’s learned about creating a Kickstarter campaign for anyone else who is considering it as a launch strategy.

Here’s Brianna…

I’ll begin by saying, I’ve never done a crowdfunding campaign before. Like ever. Knowing that I needed to create one to kickstart my business, I was on the hunt for a good resource that could help guide me along the way.

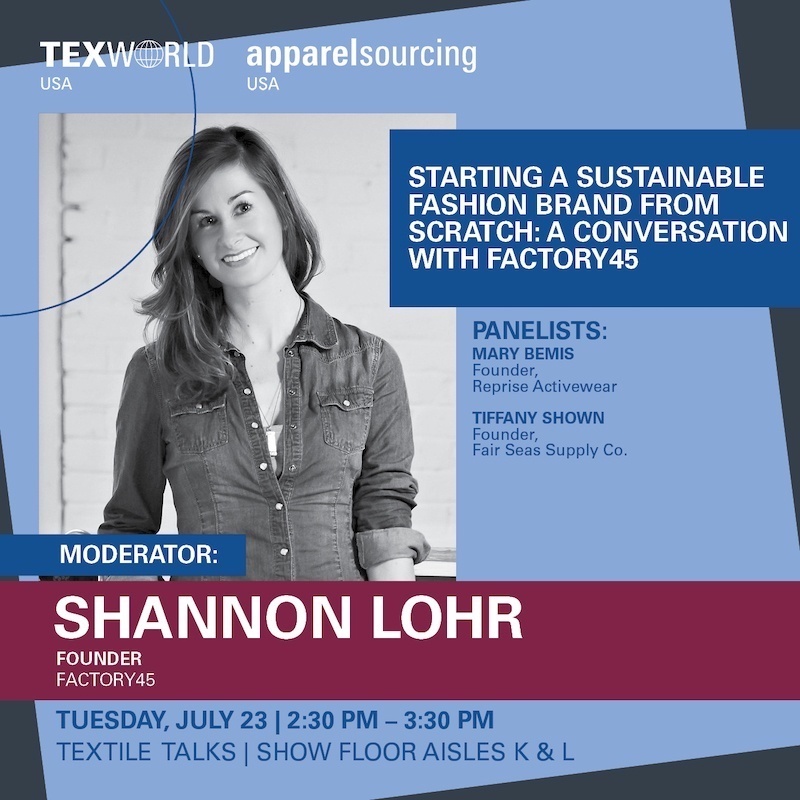

When I found out that Shannon ran one of the most successfully funded Kickstarter fashion projects at the time and had built an online course based on best practices, recommendations and preferred resources — I knew I had to take it.

It was quick, simple and incredibly applicable. Thinking through the entire crowdfunding process before beginning helped prepare me for the highs and the lows and be proactive instead of reactive.

Here are my top three takeaways:

#1. CONSISTENCY.

One of the biggest takeaways from The Crowdfunding Factory is that consistency is one of the most important parts of starting a business. More so than making a single ultra creative post or product.

It can take seven interactions with a brand before a person decides to take action with a product or service. So I knew that in order for my business to be successful, I needed to make sure my content was being seen.

I snagged up every social media account, and then I picked specific social media platforms that my target market frequented to maximize the return on investment aka my time and energy! Anact is now on Instagram, Twitter, Facebook, LinkedIn, and my personal accounts.

Consistency also means that I needed to be posting frequently. So Anact went from posting about once a day to posting 3 times a day (for now). PS: Social Sprout has become my go to for scheduling synchronized social media posts.

Three times a day seems a bit extreme; however, our backers will come from all different time zones and we believe it was important to make posts that could be seen from various time zones until our Kickstarter launches. Once we launch, we will post less, but we will now make sure we post on a schedule so that we are always consistent.

#2. RE-SHARE. 80% of your time should be spent promoting content you’ve already made.

Adding onto the consistency train, promoting your content should be a high priority. We learned not to spend all our time creating new content (blurbs for posts, pictures, etc.) and realized that we needed to share and share and share and share our current content so that more people can see it and so our time spent creating that content doesn’t go to waste.

To help with that, we started paying Instagram and Facebook to promote our posts so that it reached our target audience easier. We also encouraged our friends, family, and fans to share our content. #freeinfluencers

Prior to launching Anact, I wasn’t even active on social media. I have to say that I have been really amazed at the opportunity it holds in promoting your business and connecting with amazing people all over the world.

#3. SPREAD THE WORD.

If you’re a startup founder like me, you are most likely spending most of your time on the product creation process. We all saw what happened with FYRE Festival — a hyped up marketing campaign with a bad product is no bueno.

So once you have perfected your product, you’ll need to navigate the press circuit and promote all of your hard work so you can share with the world! Shannon’s guidance and personal press contact list was instrumental in understanding how to navigate this aspect of startup life.

Terms such as “editorial calendar” and “press pitch” have become ingrained in my vocabulary as we prepare for our Kickstarter launch.

There are many more insights and takeaways that I have gained, but the common theme in each takeaway has been that it has created confidence in myself and the crowdfunding process and for that – I am incredibly grateful!

-Brianna

Founder, Anact

Anact is short for “an act”. The simple act of creating impact. My simple act was developing a hemp-based towel that is good for all people and the planet.

When you buy a towel, you’re already taking action and making a difference. We hope you take it a step further and each time you use the Anact towels you’re inspired to take simple acts to create impact too.