Note from Shannon: This is a guest post by Savannah Fender who is currently a Master of Science candidate in the Department of Textile and Apparel, Technology and Management, College of Textiles, at North Carolina State University.

When you think of fashion and apparel what are some of the top cities that come to mind?

The majority of people would probably identify with New York and Los Angles or Milan and Paris. However, it is what’s hidden under our noses that can help entrepreneurs thrive.

Against popular belief, the sewn goods and textile industry is alive and well within the United States.

Many times the facilities are a lot closer to home than you think. Perhaps they are even your next-door neighbors.

Today, we are going to be touring Apparel Prototyping and Design Solutions, LLC (APaDS) in Pelzer, SC. With a population of just below 100 people, you probably weren’t taught about Pelzer in your eighth-grade geography class! Pelzer is about a 20-minute drive south of Greenville, SC.

There I met with Darlene Martin, the senior pattern maker at APaDS with 28 years of experience; and Elroy Pierce, Founder of APaDS with over 38 years of experience in apparel manufacturing.

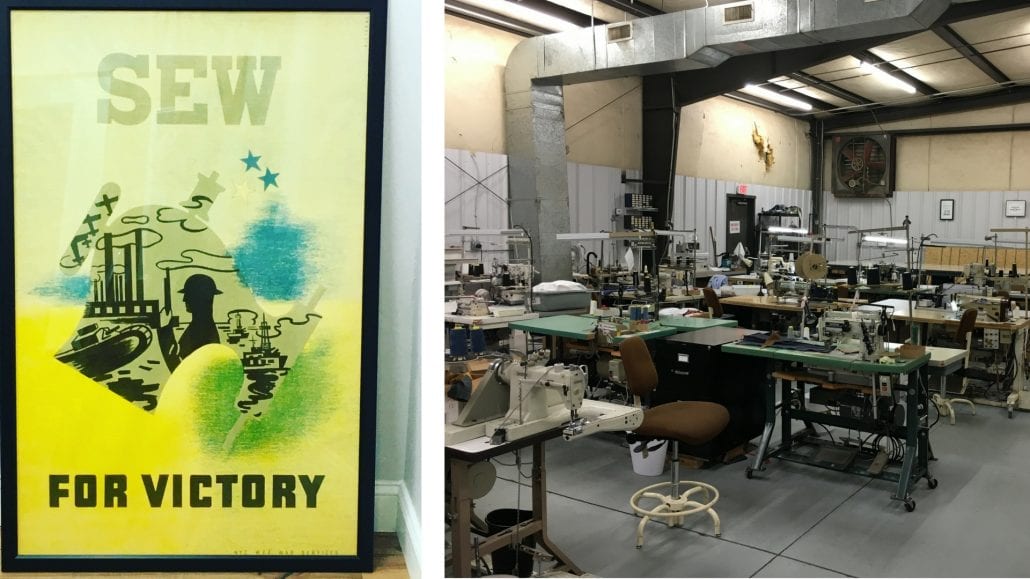

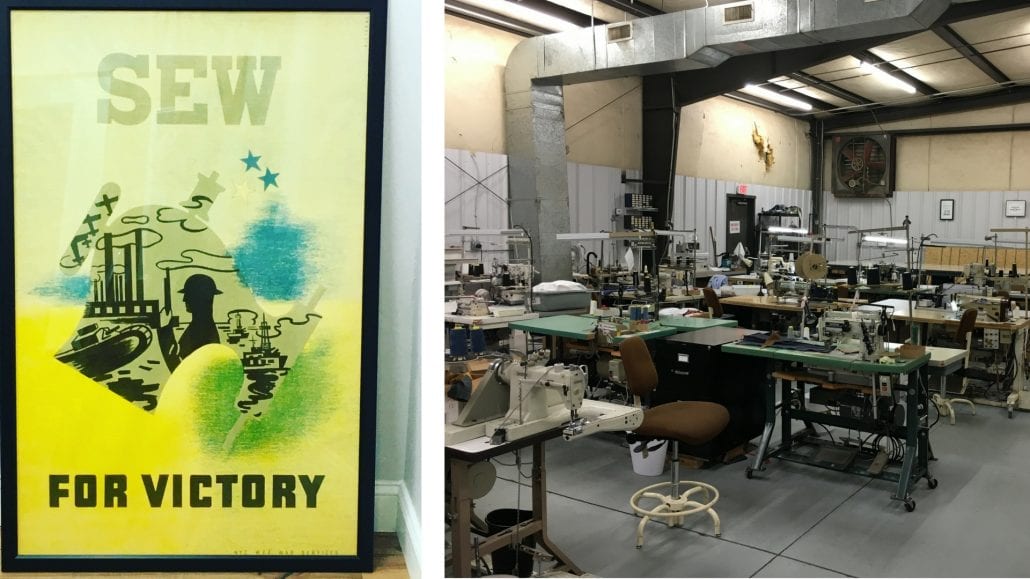

Before we got started with an in-depth discussion about domestic production, I took a tour of APaDS. The facility was established in May 2014, as a result of Clemson University making a decision to shut down Clemson Apparel Research (CAR). APaDS, where Darlene and Elroy are today is located at 6931 Hwy 29 N, Pelzer, SC, with six office spaces, a digital patternmaking room, and an open floorplan sewing/cutting room.

Darlene got started in the industry when she was in her early 20s. She had taken a home economics course in high school and discovered her passion for sewing. Darlene went to work at a local “blouse plant” and from there, her mentor taught her pattern work straight from fabric draping.

They worked for clients like Victoria’s Secret, Sears, and Coldwater Creek. As CAD (computer-aided design) programs became more popular, Darlene’s company encouraged her to go to Atlanta for a two-week program to learn digitizing and grading. Darlene hasn’t stopped working in the industry since.

Even in shutdowns she managed to keep pushing.

Today APaDS is working with about 150 different clients, including Reese Witherspoon’s brand Draper James.

When you enter APaDS you can see firsthand the passion the employees put into their work. For the people at APaDS, domestic manufacturing was what they always knew, so why move away from it?

They understand the industry has changed drastically and are willing to adapt everyday.

When asked what trades-off companies have to take to stay domestic, Elroy responded:

“There is still a large skill set in the States, it is diminishing very quickly… companies are going to have to look to semi-automation… produce smaller qualities on a faster turn time, than what they did in old production… ”

APaDS is very optimistic about the future of American manufacturing, although it will take time, they feel they are doing their part to promote domestic manufacturing and help entrepreneurs grow.

APaDS is passionate about what they are creating.

If you are looking for someone in the same time zone (or even just a few hours off) that is willing to work with you face-to-face to produce outstanding quality, this is certainly a place your products can be developed.

Breaking it down:

- What can APaDS do for you?

>> They are the front people you want to be working with before manufacturing or mass-producing. APaDS can help with your sewn product needs from pattern design, pattern grading, marker plotting, garment samples, garment costing, industrial engineering, apparel consulting, and even small runs (upon request). These are some of the initial steps you MUST take before finding a manufacturer that will work with you.

>> They are very competitive and cost varies depending on the services and needs of a client.

>> Not necessarily, however it will save APaDS some time when it comes to product development. If you don’t have a technical pack created, APaDS is more than happy to help you format exactly what you need page by page.

- Am I allowed to visit the facility?

>> APaDS loves it when their clients come for initial consultations, or later in the process to view their work. However, if you aren’t near the area don’t let that stop you! Darlene is very accessible via phone, email, and even Skype.

- What is the time frame for a returned product?

>> Anywhere from 4-6 weeks.

- What if I already have a pattern ready?

>> The timeframe may be shortened a bit, but the pattern will still need to be reviewed by Darlene for marking and digitalizing.

To learn more about the incredible people working at APaDS, be sure to check out their website here and Facebook page here.

Savannah Fender is currently a Master of Science candidate in the Department of Textile and Apparel, Technology and Management, College of Textiles, at North Carolina State University. She completed her B.F.A at Radford University in Fashion Design and Marketing. She is currently in her last semester at NC State working on her thesis, which focuses on domestic manufacturing within the sewn goods and textile industry. Savannah is passionate about garment production and helping entrepreneurs thrive!