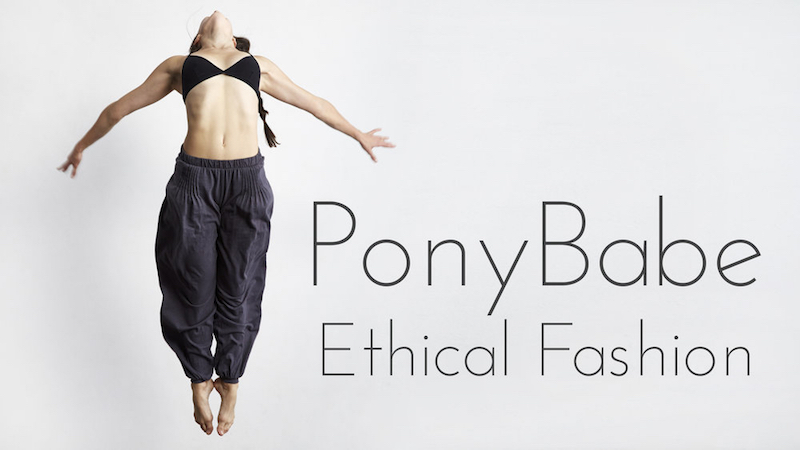

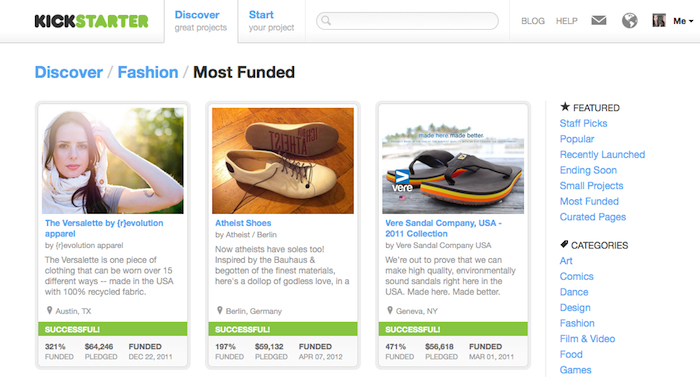

This is an interview with Factory45’er Rachel Fernbach about the launch of her brand PonyBabe (update: rebranded to Farbrook Studio). With the help of a Kickstarter campaign, Rachel is raising money (update: has raised money) for her first production run of The 24 Hour Outfit.

What are you pre-selling on Kickstarter?

PonyBabe is a line focused on creating ultra comfy, versatile wardrobe staples for women. The clothing is made from premium super soft eco-friendly fabric and manufactured in Brooklyn, NY.

The 24 Hour Outfit, now available for pre-sale on Kickstarter, is a collection of 4 pieces: a large wrap, a racerback tank top, a cardigan, and a pair of delicately pleated pants. Meant to be mixed, matched, layered, and worn on repeat – the 24 Hour Outfit is ideal for creative professionals, expecting/new mamas, yogis/meditators/dancers, minimalists, and travelers.

Why did you choose to launch your brand through Kickstarter?

I started PonyBabe with personal savings, and did not have the cashflow to fund my first production run. I needed to raise money to get that going, and also wanted to make sure there was a demand for the clothing before getting any deeper into the process. As a new label, Kickstarter is an ideal way for me to raise money while also testing the waters, and it’s an effective way to spread the word about PonyBabe.

What was the most challenging aspect of creating your campaign?

Oh my goodness. I’m not going to lie: If I had known how challenging this all would be, I… still would have done it, but at least I would have been emotionally prepared for the insanity of doing so many new things for the first time!

I would say that what has been most challenging is simply the fact that I came into this industry with very little knowledge, and have had to learn so many new things, on a constant basis. (How to get samples and patterns made, how to produce a photoshoot and video shoot, how to use social media, how to build a website… the list goes on.) It’s tiring, exhilarating, exciting, and also super cool to learn new things — but some days my bandwidth runneth low…

You’ve done months of prep. What helped you keep up your momentum and motivation?

I started building my email list very early, and though it has grown slowly, having a supportive circle of dedicated and caring people has been priceless… each time I sent out an update (even if it was to say that things weren’t going as planned), I received back an email here and there encouraging me to keep it up and make those clothes. Those little love notes really kept my spirits up when things were hard.

Can you give us a little insight into your campaign strategy? What has been working and what hasn’t worked as well?

The clothes I’m making are a great fit for a lot of different lifestyles. With that in mind, I honed in on a few niches – yoga, dance, minimalism, eco-fashion, American-made, and maternity – and researched blogs, boutiques, magazines, and influencers who might have an interest in seeing PonyBabe get funded. It’s pretty early in my campaign, so I’m still waiting to see what winds up working best!

What seems helpful is connecting through my networks – i.e., friends of friends seem much more likely to want to help… but I’m not letting that stop me from reaching out to others as well. As in all arenas of life, relationships are key: it’s important to make personal connections, and make offers to give instead of just making requests to receive.

What do you do when self doubt starts to creep up?

Notice it, allow it to have some space, then choose to focus on the positive. I actively shift my attention to what is going well, while also acknowledging that this is a stressful experience, and it’s normal and healthy to feel a little nervous or worried from time to time.

My nerdy self-encouragement mantra right now is “People love me and want me to succeed.” It’s surprisingly motivating! 🙂

What’s your favorite reward being offered in your campaign?

The Whole Outfit, of course! Each piece is great on its own, but putting on the whole outfit is pretty much a perfect recipe for instant comfy cozy bliss. I love how it makes me feel like cuddling up with a mug of tea and a good book.

If you had one piece advice for someone considering launching a Kickstarter, what would it be?

Go for it! And ask for help from people, because it’s a lot for one person to take on.

You can check out Rachel’s campaign for The 24 Hour Outfit by PonyBabe here. To read more about Rachel’s experience in Factory45, read her alumni story here.