Six years ago, I was 24 and had just gotten back to the States after spending two years “bartending my way around the world.”

I had once been the girl who envisioned herself in the corner office — but after two years abroad, I knew that I would never get a “real job.”

I wanted to create something bigger than myself. I wanted to start a business that would allow me to wake up every morning and go after my dreams. In typical GenY fashion, I didn’t want to help build someone else’s dream.

It was a divine twist of fate when I got a Facebook message from a friend shortly after I got home. She said she was going through a “quarter life crisis,” dreading the possibility of sitting in a cubicle all day, and suggested we start something together.

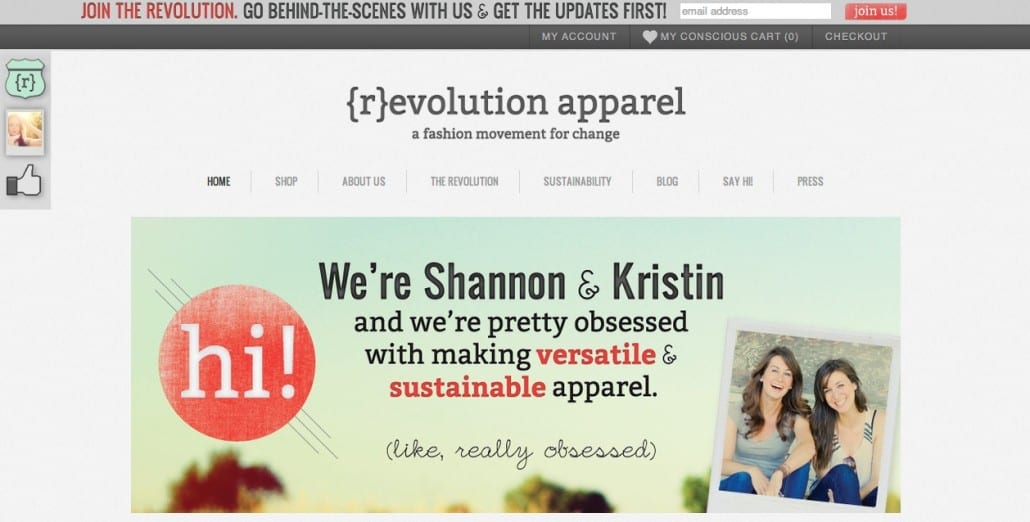

That “something” turned out to be a sustainable apparel company.

Of course, it didn’t happen immediately.

Our plan was to create a company that would be 100% made in the USA, using fabrics and materials that did the least amount of harm to the environment as possible.

But we quickly found out that having a plan wasn’t enough. We were naive, unversed in industry lingo, and had zero connections in the fashion industry. It became obvious very early on that what we were trying to accomplish wouldn’t be easy.

We spent money on the wrong things, made every mistake possible, wasted time pursuing leads that ended in dead ends and continuously took two steps back with every one step forward.

Looking back at the emails I sent to fabric suppliers, I now know that my inquiries surely got a swift click of the delete button. I didn’t know how to talk to industry veterans, I had no idea how to walk “the walk,” and it showed.

But after a year and a half, having nearly depleted both of our savings accounts, the stars aligned.

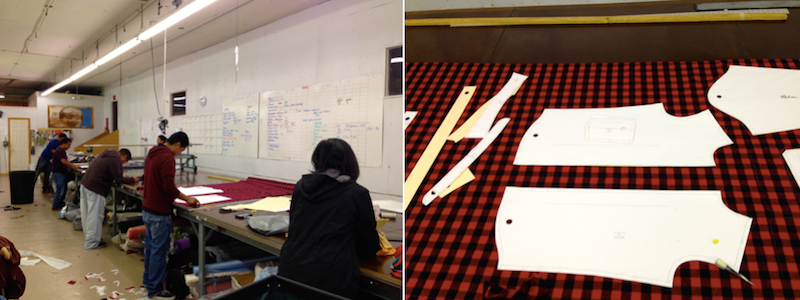

We received a response about a private label inquiry we had sent to a contact form. After a few meetings, we made the decision to source and manufacture our first production run under the guidance of a company who had done it before.

The company was a startup itself but was farther along and had the production infrastructure that we lacked. They also had the knowledge, connections and reputation. After pushing forward solo for so long, we had found someone to take us by the hand and walk us through the process.

We had finally found the mentorship we needed.

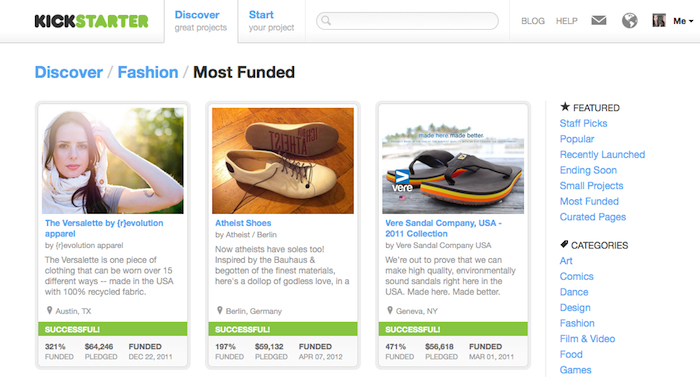

A month later, we broke records launching the highest-funded fashion project in Kickstarter history.

We quadrupled our first production order, were featured in The New York Times, and started our business with 1,400 customers.

Fast forward to today and I’ve been able to acquire the knowledge, skills, connections and reputation that I didn’t have when I was first starting out.

In the last few years, I’ve helped over 70 entrepreneurs set up supply chains in the U.S., source sustainable materials and bring their products to market.

Factory45 is the program I created for entrepreneurs, like me, who have a vision and a plan but need the mentorship and resources to get started.

I’ll be looking for a crew of committed designers, makers and entrepreneurs who want to join me in creating a more ethical and transparent fashion industry. If that sounds like you, mark your calendar.