The past five days have been a whirlwind — to put it lightly.

It started on Friday when I received three emails from people interested in sewing masks for medical workers.

As the day went on, I kept hearing from our factory partners that they wanted to help, but they didn’t know where to send the masks.

So much of my experience through Factory45 is based on connecting entrepreneurs with manufacturers.

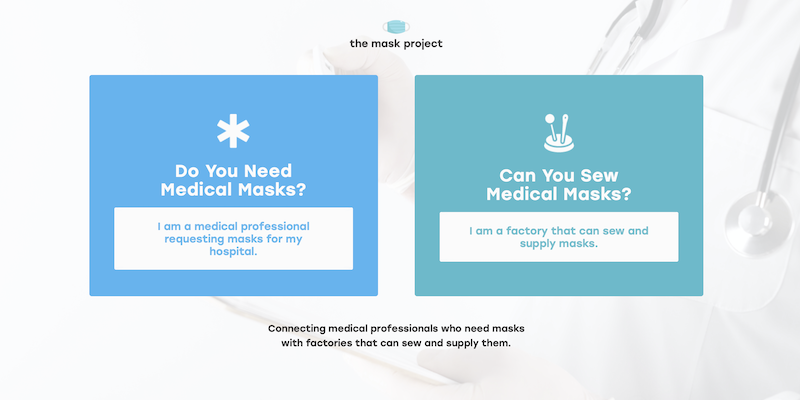

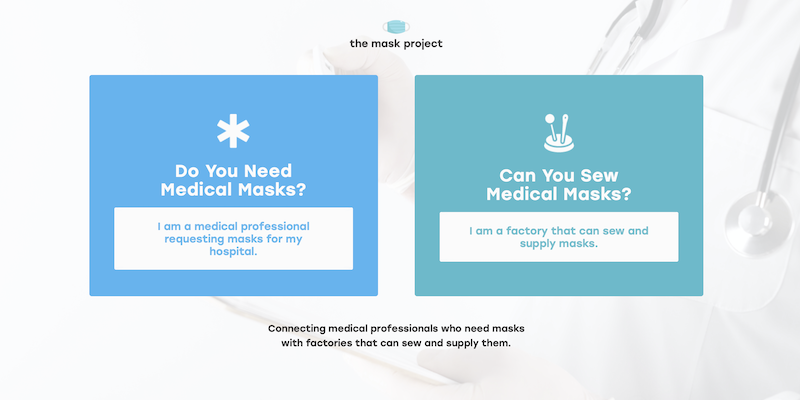

It got me thinking about how I could translate that into connecting hospitals with manufacturers.

And that’s how The Mask Project was born.

In record time, we launched a website on Saturday night (thanks to Emily Belyea Creative) and with the help of a 70-person email chain of sustainable fashion influencers, we started spreading the word about the project on Sunday.

Kathryn and her team at Good Clothing Company got to work designing a more efficient pattern for the mask.

JOANN Fabrics stepped in to donate thousands of yards of fabric and as of Tuesday afternoon, we have 54 factories willing to sew medical masks.

We’ve also received requests for over 100,000 masks from hospitals all over the country.

I’ve estimated that with our factory network, we could manufacture over 500,000 masks per week — two million masks per month — for medical professionals across the U.S.

But here’s the thing: right now, these factories are donating their time and labor.

While they’re pivoting their business models to help with the mass shortage of medical supplies, they also need to keep themselves in business.

This is different from the home sewers and hobbyists making 100 masks a week and donating them. It’s still amazing, but it’s different.

The real impact in this mask shortage can be made by our network of U.S. factories that want to keep their sewers employed.

Over the past 24 hours, I’ve learned more about hospital supply chain, government funding and the intricacies of budget restrictions than I ever thought I would.

It’s clear that the city government and hospital funds are maxed out. The money that they do have should be spent on N95 respirators and ventilators directly in contact with COVID-19.

The masks that we’re making are meant to be used in sterile environments and operation room settings to free up the “real masks” for treating contagious disease.

And while I’m working on strategic partnerships with influencers who can amplify the message for funding, it’s ultimately going to come down to individual donations.

So, in what I thought would be a very different blog than what I’m posting today, I’m asking you to consider supporting these factories that want to help and that also want to stay in business.

You’ll see a “Donate” button on The Mask Project website here.

In the meantime, I’ll be working on alternative ways to get mass amounts of funding for our manufacturing partners, while continuing to research hospital supply chains (if this is your area of expertise, please email me!)

Thank you to so many of you who have already spread the word and supported the project on Instagram this week.

Our community is the best.

Gratefully,