I was first introduced to the founders of Sword & Plough during their Kickstarter campaign in the spring of 2013. Sisters Betsy and Emily Nunez launched a campaign (that blew their goal out of water) to produce a quadruple bottom line company that works with veterans to repurpose military surplus fabric into stylish bags.

A year later, I met Betsy in Boston to hear more about the behind the scenes of growing Sword & Plough. Since our coffee chat, S&P has seen some amazing traction with its debut on The Today Show, as well as features in Business Insider, Inc. Magazine, Refinery29 and many more.

Having started from ground zero and building the company into what it is today, Betsy is sharing her best start-up advice for early-stage companies that are ready to embark on their journey.

1.) What inspired the creation of Sword & Plough? What are the ethics and values behind your company?

My sister, Emily, and I grew up in a military family. After hearing so many meaningful stories from our father, uncle, and cousin about their time in the service, Emily was inspired to serve herself. She was particularly inspired by the humanitarian missions that our dad was deployed on and the counterinsurgency research he conducted that was put into action. She knew she wanted to serve in the military, and we both knew at a young age that we wanted to make a positive impact in the world, just as our family members had.

As a result of Emily’s time in Army ROTC during college and growing up in a military family, she was keenly aware of the incredible amount of military surplus waste, as well as the state of veteran unemployment. This inspired her to take something that is often wasted and upcycle it into a beautiful product with a powerful mission.

The result is our company Sword & Plough.

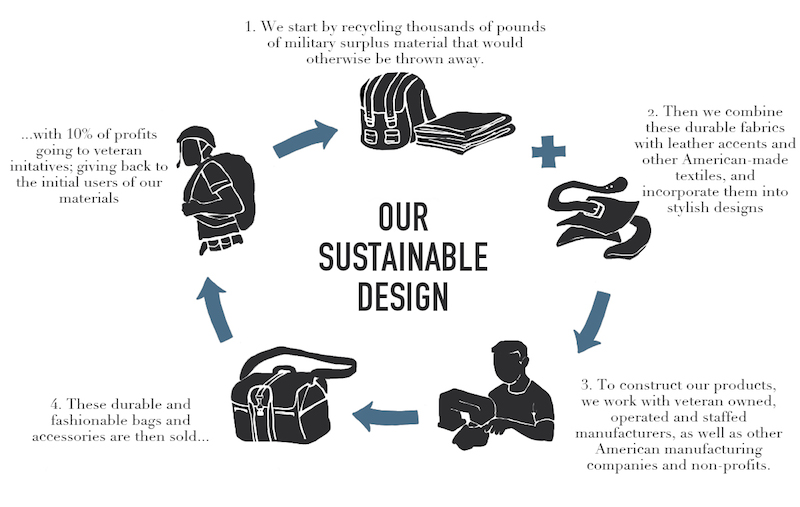

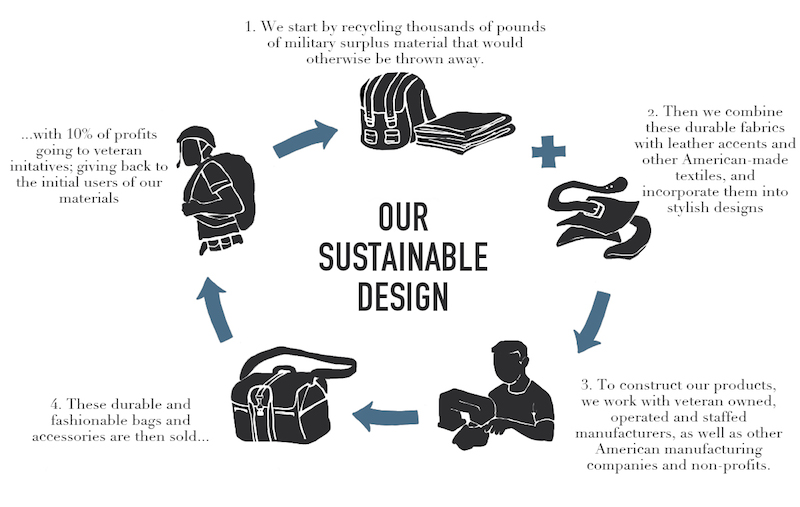

Today, our team re-purposes military surplus materials into stylish bags that are made by American manufacturers that are veteran owned or operated. We also donate 10 percent of the profits to veteran organizations that align with our mission to strengthen civil-military understanding, empower veteran employment, and reduce waste.

We are a quadruple bottom line fashion and accessories business focused on people, our purpose, care for the planet, and profitability (a key component that allows us to further our impact). Our team has built our business model to reflect a life cycle and we’ve worked hard to shape the brand’s ethos with impact at every stage. To date, Sword & Plough has up-cycled over 15,000+ pounds of military surplus, supported 38 veteran jobs, and sold over 5,000 products.

2.) What was the most difficult part of setting up your supply chain? What hurdles did you have to get over in the process?

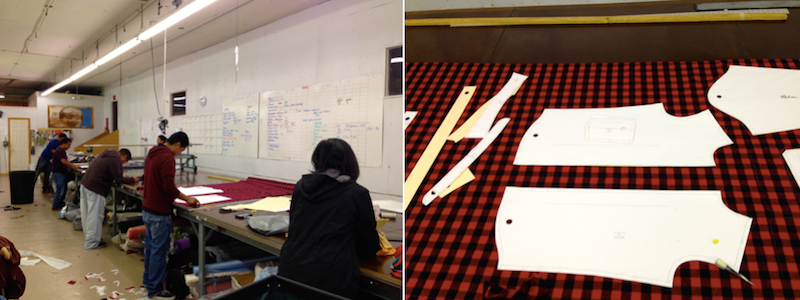

The most challenging part of setting up our supply chain was learning everything from scratch, setting it up, and ‘putting out fires’ or problem solving as issues arose. We knew from the beginning we wanted to do our manufacturing in the U.S. and work with U.S. partners and suppliers, but no one on our team had specific knowledge or experience with manufacturing or creating a supply chain. Building our long term supply chain for large scale S&P production happened after launching on Kickstarter, all while the majority of our team was located in different time zones — Emily, our CEO, was deployed and serving with the U.S. Army in Afghanistan at that time.

First hand experience taught us that relying on so many different pieces (manufacturing, shipping, expenses, other people and even the environment) can create surprises or ‘speed bumps.’ What you thought was going to take one month to implement can quickly extend to two or even three months!

These ‘speed bumps’ were the sort of setbacks that if not corrected the second time around, can quickly crush an early stage business, or best (of the worst) case scenario, lead to unhappy customers.

We worked hard to absorb as much information as possible and then make adjustments and implement new strategies as we moved forward.

Here are a few key things we learned:

- Find sources that are a match for large scale production regardless of the stage you are at.

- Find sources or partners that carry items that are consistently re-stocked or are regularly available in large quantities.

- Ensure that the companies you are working with are in good financial standing and will be a long term partner.

- Ask the supplier or partner to fill out a CSR (Corporate Social Responsibility survey) or ask them questions to ensure their processes meet your values.

- Do test runs for time, cost, etc.

- Get quotes, samples, shipping timelines, lead times, and cost in writing prior to purchasing.

- Find an effective and diligent way of communicating with your manufacturer (Whether it be planned calls, weekly/daily visits, having them regularly update a master spreadsheet with production progress).

- Find mentors specifically skilled and experienced in retail distribution, operations, logistics, and supply chain.

Manufacturing within the U.S., communicating with all parties in the same language, as well as being located in the same country has helped us do all of the above, act or react in a very timely manner, and has allowed us to feel a lot more comfortable with our processes once we were set up.

3.) What mistakes or challenges have you learned from while setting up and running Sword & Plough?

We knew there would be a lot of challenges and new roles, facets, and foundations that were going to be essential to fulfilling our dream of turning S&P into a well functioning business.

When building a startup, you haven’t learned how to do everything yet and you’re likely going to be very limited with resources and working capital. A lot of the advice and help we received early on is still priceless today.

We’ve never been afraid to ask for help or to ask the questions that will help us problem solve or plan our vision further. It wasn’t easy (early on) to be focused on an idea that hadn’t gained momentum yet, or something that people weren’t aware of or didn’t understand. We’ve learned through early challenges that nothing worth doing comes easy and there’s a lot to learn when you’re building something from scratch. It’s your ability to work when work isn’t easy that makes the difference.

The best part about our business life is the uniqueness and pride that comes with seeing our idea through and gaining momentum. Each and every day, regardless of the challenges that present themselves, we feel like we’ve won the lottery because our team gets to build something that is our own , through our vision and share it with the world.

, through our vision and share it with the world.

4.) What is your main marketing strategy? You’ve also gotten some great press – how did those opportunities come about?

4.) What is your main marketing strategy? You’ve also gotten some great press – how did those opportunities come about?

Our main marketing strategy is to build engaged groups through word of mouth, social media, press, and email marketing. A lot of the opportunities and features that we have received to date have come from a very strong launch when we entered the market on Kickstarter in April 2013.

Here are three things that we found helpful to think about when launching our brand and getting the word out:

1. Define your goal and create your pre-launch, launch and post-launch plan. Define your vision for your audience, brand, community, and story. Be as detailed as you can and think about what you need in terms of funding and your goals for marketing, branding, production and customer experience.

2. Activate and engage your network. Make an early, large, public and online announcement to your commitment to build your product or launch. From that point on, commit to building as much awareness as possible around your product, campaign, or launch.

3. Ensure a wide audience for your campaign (to expand even beyond your network):

- Share your product or idea with as many friends, family and acquaintances as possible.

- Organize feedback sessions and ask for their advice, opinion and real time feedback. Collect as much information as possible and listen.

- After you’ve connected with someone in your target market, ask if there’s anyone they think you should meet or speak with who could provide additional support, and don’t be shy about asking for a direct introduction.

- As you’re having the conversations, give people the opportunity to sign up for launch alerts or updates.

- Create engaging content and tell every aspect of your story.

- Develop brand evangelists who will talk about your product and story.

- Create and build your brand’s resources (social media platforms, media packet, press release, business cards, pitch postcards, text lists, email lists, photography and campaign videos).

- Build a media list of bloggers and publications that have synergy with your idea, mission and product. Keep in mind that many of the bloggers you reach out to are getting hundreds of emails each day. You need to make your story stand out, and the easiest way to do that is often with a direct introduction.

- Create new contacts outside of your own network by attending meet-ups, events, presentations, pitch competitions, events in the industry you’re looking to enter, and be an active member of communities that have synergy with your mission

- We highly encourage you to reach out to your already existing network — your friends and family. Don’t be afraid to reach out to your network and ask for support, in the form of help or pledges, but perhaps more importantly, contacts.

5.) What advice do you have for designer entrepreneurs who are just starting out?

If we could pass along advice, our top ten would be…

1. Take your ideas seriously from the start. Every idea is worth serious consideration (at least a five minute brainstorm), no matter how absurd or impossible it may seem at first. Believe in the power of an idea. Test your idea continuously and ask questions. Push yourself to drive the idea from concept into reality.

2. Ask for feedback every step of the way.

3. Dream up the biggest vision possible, start wherever you are and start small.

4. Nothing is impossible or out of reach for people that continuously try and go after what they want.

5. Push through the challenges and overcome any sized obstacles by gathering information, seeking help and broadening your perspective.

6. Find mentors that are successful and experienced within your industry.

7. Constantly developing relationships is essential for business growth.

8. Build your own community or seek out the ones that will either be very supportive and the most critical of your idea. Both will make you better.

9. Seek out opportunities. They are fuel for gaining momentum, and opening the door for communication between your business and audience is key.

10. Always thank people and express gratitude.

—

Photos courtesy of Sword & Plough, So Freaking Cool, Druammons, Made Close, Go Verb & Super Compressor.

“I wish I’d known that, no matter how much you love the product, you absolutely have to ensure that: (a) you can get it produced fairly simply/easily (to avoid loss of time/sleep and potential burnout); and (b) the margins are healthy enough that you can not just sustain, but actually grow, the business (or you at least see a clear path to get the margins to that place).

“I wish I’d known that, no matter how much you love the product, you absolutely have to ensure that: (a) you can get it produced fairly simply/easily (to avoid loss of time/sleep and potential burnout); and (b) the margins are healthy enough that you can not just sustain, but actually grow, the business (or you at least see a clear path to get the margins to that place).  “I wish I had known that fashion is about breaking the rules, not following them. That theory is applied to design all the time, but the business of fashion should also be about challenging the status quo, not following the calendar, not following what everyone else does and not doing as we’re told. That’s the only way change will happen in this industry and I wish I had known that sooner.”

“I wish I had known that fashion is about breaking the rules, not following them. That theory is applied to design all the time, but the business of fashion should also be about challenging the status quo, not following the calendar, not following what everyone else does and not doing as we’re told. That’s the only way change will happen in this industry and I wish I had known that sooner.”  “I wish I had known which parts of the sampling and manufacturing process would be good for me to figure out on my own and which steps are vital to have carried out by an experienced professional. There were some things I realized I should have done myself, and a few things that would have saved me time and money in the long run had I outsourced.

“I wish I had known which parts of the sampling and manufacturing process would be good for me to figure out on my own and which steps are vital to have carried out by an experienced professional. There were some things I realized I should have done myself, and a few things that would have saved me time and money in the long run had I outsourced.  “I wish I had known how much clarity I had starting off—that I felt content and confident knowing what I was setting out to do and who I was trying to speak to. Had I taken stock of this intuition at that early stage, it would have been much easier as my audience grew to know when I’m being true to myself and the narrative I am trying to tell. Even now, as I slowly start to roll out new work, I realize that the hardest thing I have to do in this (post) post modern, socially nomadic world we live in is to just fiercely be myself.”

“I wish I had known how much clarity I had starting off—that I felt content and confident knowing what I was setting out to do and who I was trying to speak to. Had I taken stock of this intuition at that early stage, it would have been much easier as my audience grew to know when I’m being true to myself and the narrative I am trying to tell. Even now, as I slowly start to roll out new work, I realize that the hardest thing I have to do in this (post) post modern, socially nomadic world we live in is to just fiercely be myself.”  “I wish I had known just how important it is to have an audience to launch to. If you want a product-based business, first start by generating a following. This could be through a blog, via Instagram or Twitter. Build up a community of people that is in-line with your future product. When you’re ready to launch you’ll have an invested group of people you can turn into customers.”

“I wish I had known just how important it is to have an audience to launch to. If you want a product-based business, first start by generating a following. This could be through a blog, via Instagram or Twitter. Build up a community of people that is in-line with your future product. When you’re ready to launch you’ll have an invested group of people you can turn into customers.” “I wish I had known that finding great US manufacturing is kind of like speed dating. If it doesn’t seem like it’s going to work out, make a polite exit, but move on. Their existing operations shouldn’t have to adjust much at all to achieve the product to be produced. It should be a very close fit from the very beginning.

“I wish I had known that finding great US manufacturing is kind of like speed dating. If it doesn’t seem like it’s going to work out, make a polite exit, but move on. Their existing operations shouldn’t have to adjust much at all to achieve the product to be produced. It should be a very close fit from the very beginning.