“We believe when a woman is given an opportunity to earn income, she will invest in her children first – a strategy shared by organizations around the world. We also understand that women from low-income communities face major barriers to economic success for themselves and their children.”

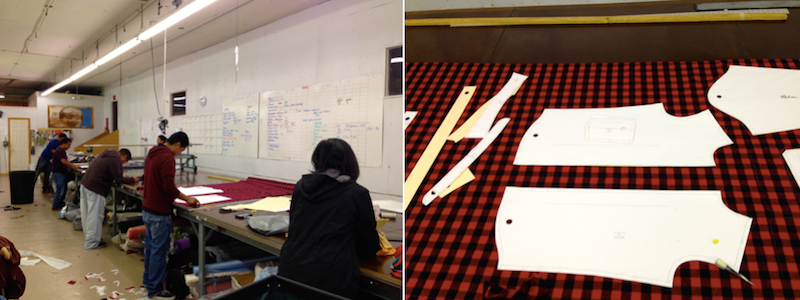

This is the philosophy behind Southwest Creations, a cut and sew facility in Albuquerque, NM that proves a sustainable business can be driven by a social vision. I spoke with executive director Susan Matteucci on the phone a few weeks ago about how Southwest Creations was started, how it has grown and where the opportunities lie in U.S. manufacturing.

Susan was also gracious enough to offer her own advice to designers looking for a domestic production partner. Read her interview below:

F45: Tell us about Southwest Creations. How did you get started? How long have you been in business? What was the catalyst for opening a manufacturing facility?

Southwest Creations is a women-driven factory that provides contract cut-and-sew handwork and kitting production services. Our clients range from West Elm to a dog collar company for sewing, and multinational to local businesses for kitting and assembly.

Southwest Creations was founded in 1994 and we just celebrated our 20th anniversary.

We operate a successful social enterprise that was founded to create economic opportunities across generations.

F45: What advice do you have for new designers who are looking for a sewing contractor in the U.S.?

- Know your product inside and out – know all of your suppliers, components, materials, etc.

- Have your pre-production samples and patterns 100% to your satisfaction before going to a production contractor.

- The designer should be the expert on his/her product.

- As a production contractor, our minimums are 250 per style and that can include three colors and sizes.

F45: What are some of the things that a designer should look for and ask about when reaching out to a sewing contractor?

I would ask for references from companies that are similar. I would make sure the company is large enough to handle the agreed upon deadline. I would ask for production samples. It’s best to be within a days drive so you can see the facility and get to know the staff.

F45: What are the red flags or things a designer shouldn’t do or say when looking for a production partner?

- “I have a dress I want you to copy for me.”

- “I don’t know where to get my material.”

- “Can you make five?”

- Asking for a price for something over the phone that the production partner has never seen.

F45: What sets Southwest Creations apart?

We have an excellent reputation and receive highest ratings for quality, communication, customer service and delivery with competitive pricing. The icing on the cake is that we provide many opportunities for our employees from onsite daycare for $.25/hour to a path to education program for employees’ kids, plus an additional 300 families in our community. By working with us, you get more than just great service, you are part of a movement to alleviate poverty.

—

For more information on Southwest Creations, you can visit the website here.

Photos courtesy of Southwest Creations and The Albuquerque Journal.