First, thank you so much for your support in spreading the word about The Clean Living Podcast last week!

I know most of you follow me because you’re looking for help in launching your sustainable fashion brand, so I really appreciate your patience as we paused “fashion related” content this past month.

But let’s get back to it, shall we?

I have three new YouTube videos for you below about product testing, legal protection and “Made in the USA” — pick your own adventure : )

[NEW] You spend years dreaming up the perfect apparel product. You spend months meticulously creating it. You tweak and stitch and hem and haw over it until… It’s perfect. But have you tested it to make sure it’s also perfect for your customer? In this episode, I’m sharing the two most important phases of product development.

[NEW] You spend years dreaming up the perfect apparel product. You spend months meticulously creating it. You tweak and stitch and hem and haw over it until… It’s perfect. But have you tested it to make sure it’s also perfect for your customer? In this episode, I’m sharing the two most important phases of product development.

How do you move forward through the production process without your unique product being knocked off? There are the legal routes to help protect yourself, and then there are common sense precautions you can choose to implement. In this video, I’m sharing them with you.

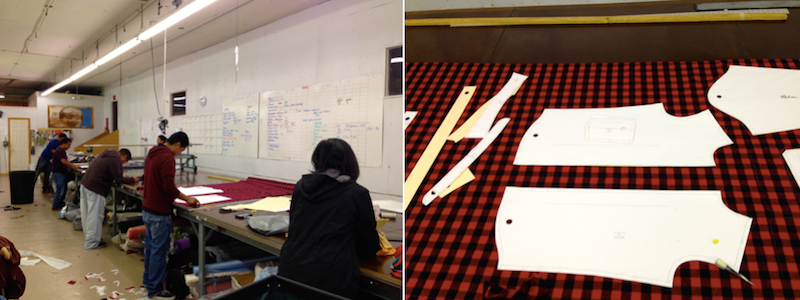

How do you create a sustainable fashion brand that’s made in the USA? While navigating the world of sewn manufacturing may be new and probably a little intimidating, there are ways to set yourself up so that you don’t come off as a “newbie.” I’m sharing five tips for creating a “made in the USA” apparel company.

How do you create a sustainable fashion brand that’s made in the USA? While navigating the world of sewn manufacturing may be new and probably a little intimidating, there are ways to set yourself up so that you don’t come off as a “newbie.” I’m sharing five tips for creating a “made in the USA” apparel company.

THIS WEEK ON THE PODCAST

Listen on Apple Podcasts here | Listen on Spotify here

CLEANING SUPPLIES Have you ever thought about the ingredients in your household cleaning products? Listen to this episode to detox your cleaning supplies.

LIPSTICK When I found out one of my favorite cosmetic products contains a neurotoxin, I was so tempted to turn a blind eye. Instead, I switched to these clean beauty brands…

TOOTHPASTE Did you know there are ingredients in some of our most popular toothpastes that are actually banned in Europe? Here’s what I did to change my family’s oral care.

Have a great week and don’t forget to VOTE on Tuesday!