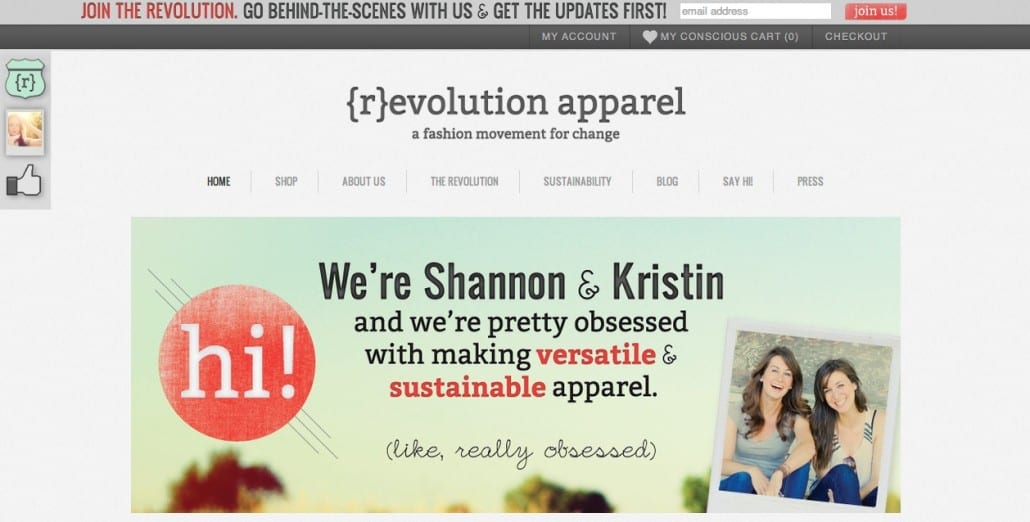

The winter of 2011 was a tough one. I had been trying to set up a supply chain for my clothing company for five months and by February, my co-founder and I had hit a mental and logistical standstill.

Looking back, five months seems like nothing. But for two driven, go-getter types, every ignored email and unanswered phone call was a mini blow to our motivation.

We simply couldn’t figure out what we were doing wrong. How was it possible that not one fabric supplier, factory or sew shop would give us the time of day?

We were at our wits end when we got a reply from a designer who said he could make our first samples. We didn’t have fabric or materials yet, but at least samples would feel like progress.

When we got on our first phone call with him he was adamant that we should fly to North Carolina to meet him. We could go over everything, work face to face and make a plan of attack for moving forward.

Resting our hopes on the chance that this person could also introduce us to a fabric supplier or a manufacturer, we booked flights for the following weekend.

All things considered, our weekend in North Carolina was weird.

We checked into a hostel in downtown Asheville and immediately went to a nearby bar where the designer had told us to meet him.

What ensued was a three hour “happy hour” in which he continued to slug beer after beer while not once mentioning our business, our design ideas or why we were there.

Promising that he would get to “it” eventually, we arranged to meet the following day at his home.

If this sounds sketchy, remember that a lot of designers / samplemakers / patternmakers work out of their homes. Also, remember that we had flown 1,000 miles, spent our savings on flights, and felt like we had no other option.

Desperation puts you in interesting situations.

We spent several hours the next day in his basement going over our sketches, spec sheets and designs and we decided that we would start with just one sample to test the waters.

He said he would create a prototype for our “maxi dress” design and ship it to us in two weeks. We left North Carolina feeling hopeful and cautiously optimistic.

Turns out, we didn’t receive our sample in two weeks.

It showed up in four weeks and when I pulled it out of the box, it looked nothing like our original design.

Instead of being full length, it was knee-length.

Instead of a sweetheart neckline, it had a scoop neck.

Instead of spaghetti straps that tied around the neck, it had thick straps that went straight back.

To top it off, he had included a “sash” to be tied around the waist in a bow!

My co-founder and I got on Skype (we didn’t live in the same city) and I showed her a dress that couldn’t have looked more different than the one we designed.

We had just spent hundreds of dollars on flights, hotels, a rental car and other travel expenses and we still owed money to pay for a sample we couldn’t use.

It was a critical moment and I had reached a breaking point.

I was mad at myself for not listening to my gut, I was mad at the designer for making us fly across the country, and I was mad that we listened to him.

All signs pointed to: You’re crazy for thinking you could do this.

Quit now.

And that would have been a much easier option — except that’s not how dreams work.

I was either going to do this, despite how freaking hard it would continue to be, or I was going to walk away.

Thank goodness, I decided to keep going.

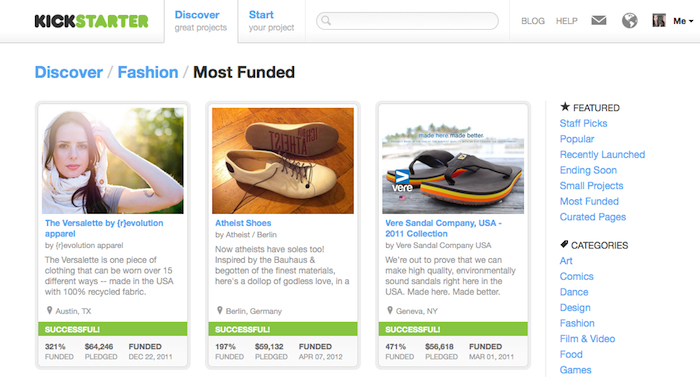

To be fair, it didn’t get any easier in the following eight months. But we did make some big decisions and changes to simplify our business idea from a line of 10 pieces to just one piece that could be worn multiples ways.

We launched our Kickstarter, becoming the highest-funded fashion project, and found the mentorship from someone who had done it before. That partnership single-handedly helped us push forward and go into production with 4x the capital we had planned on.

When I was wandering through this industry uncertain about what to do next, I found someone to help me.

I hope I can be that someone for you.

Everything you need to launch the business of your dreams is within your reach.